Offset printing, also known as offset lithography, is a widely used printing technique known for its high quality, precision, and versatility. Here’s everything you need to know about offset printing:

1. How It Works:

- Offset printing is based on the principle of lithography, which utilizes the repulsion of oil and water to transfer an image from a printing plate to a rubber blanket and then onto the printing surface.

- The process begins with creating printing plates, typically made of aluminum or polyester, which are etched with the desired image using a photosensitive emulsion.

- Ink is applied to the printing plates, where it adheres to the image areas while being repelled by the non-image areas.

- The inked image is then transferred from the plates onto a rubber blanket cylinder, which in turn transfers the image onto the printing surface, such as paper or cardboard.

- Offset printing is capable of producing high-quality prints with sharp detail, rich colors, and consistent results.

2. Advantages of Offset Printing:

- High Quality: Offset printing produces sharp, detailed prints with accurate color reproduction and consistent results, making it ideal for high-end projects and commercial printing.

- Versatility: Offset printing can accommodate a wide range of substrates, including paper, cardboard, plastics, and metal, making it suitable for various applications such as books, magazines, packaging, and promotional materials.

- Cost-Effective for Large Runs: Offset printing is highly cost-effective for large print runs due to economies of scale, making it the preferred choice for high-volume commercial printing.

- Pantone Matching System (PMS): Offset printing allows for precise color matching using the Pantone Matching System (PMS), ensuring accurate reproduction of brand colors and corporate identities.

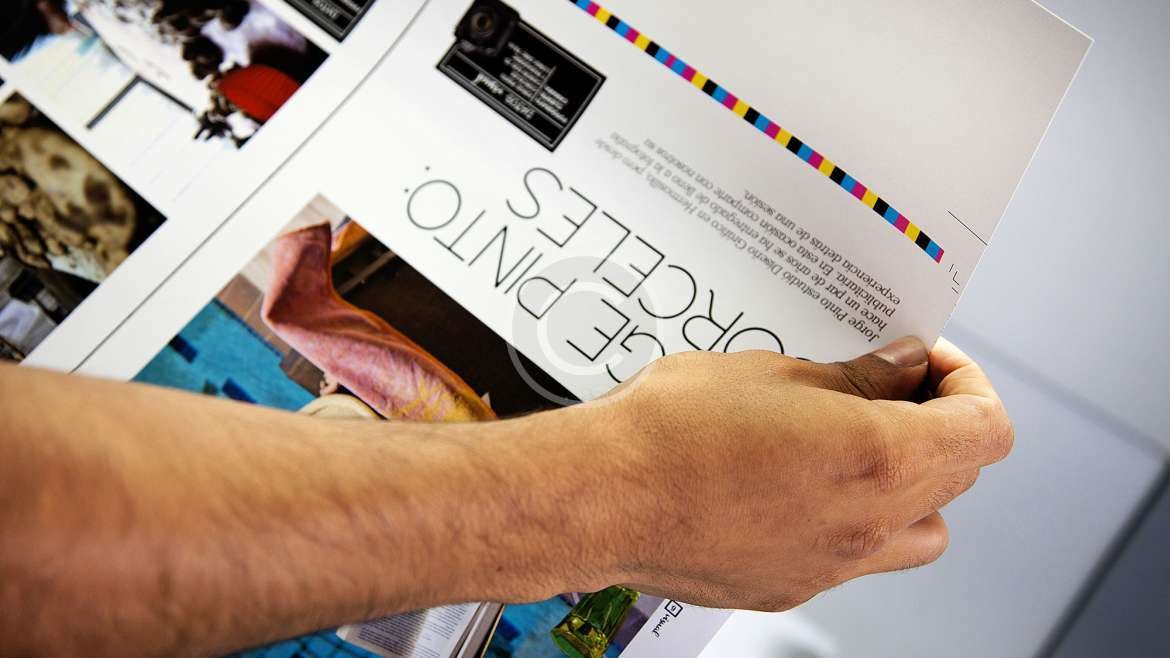

3. Process Color Printing:

- Offset printing commonly uses the process color model (CMYK), which combines cyan, magenta, yellow, and black inks to create a full spectrum of colors.

- By overlaying tiny dots of these four colors at different percentages, offset printing can achieve a wide range of hues, shades, and gradients, resulting in vibrant and lifelike prints.

4. Prepress and Setup:

- Prepress is a crucial stage in offset printing, involving tasks such as image processing, color separation, plate imaging, and proofing to ensure accurate and consistent results.

- Offset printing requires meticulous setup, including plate mounting, ink mixing, and paper feeding, to achieve precise registration and ink coverage.

5. Applications of Offset Printing:

- Offset printing is used for a variety of applications, including:

- Books, magazines, and newspapers

- Brochures, flyers, and catalogs

- Packaging and labels

- Stationery and business cards

- Posters, calendars, and promotional materials

6. Environmentally Friendly Options:

- Offset printing offers environmentally friendly options, such as soy-based inks and eco-friendly paper stocks, to minimize environmental impact and meet sustainability goals.

In conclusion, offset printing is a versatile and reliable printing method known for its high quality, precision, and cost-effectiveness. Whether you’re printing books, brochures, packaging, or promotional materials, offset printing delivers exceptional results that meet the highest standards of quality and professionalism.